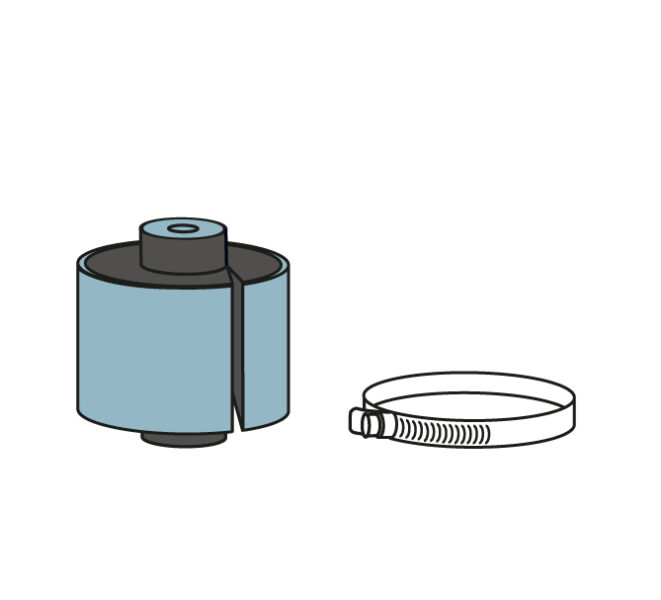

Some suspension bushings are constructed in a slightly different way than the traditional one. An example of this are bushings that have a longitudinal cut on the outer sleeve (and part of the damping element). This type of bushing in its initial state has a diameter larger than the socket in which it is to be installed. To properly install this type of bushing, it must be compressed for assembly, and then the bushing expands in the socket and thus becomes immobilized. It is best to use a metal hose clamp to install such a bushing.

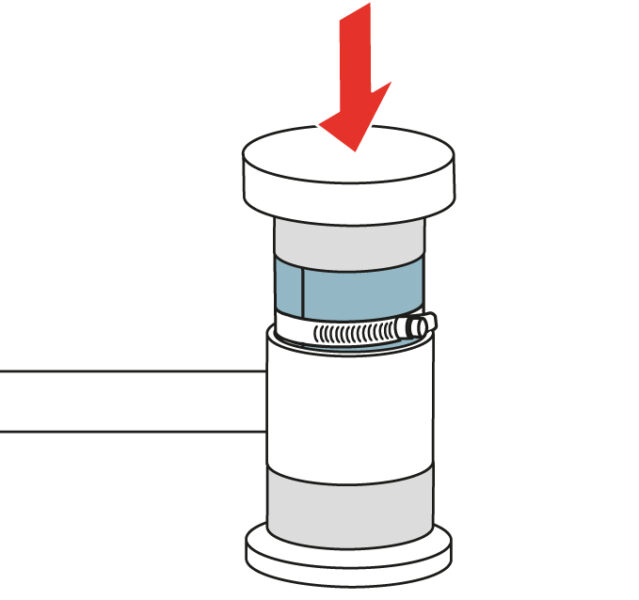

5

Press the bushing in to the clamp.

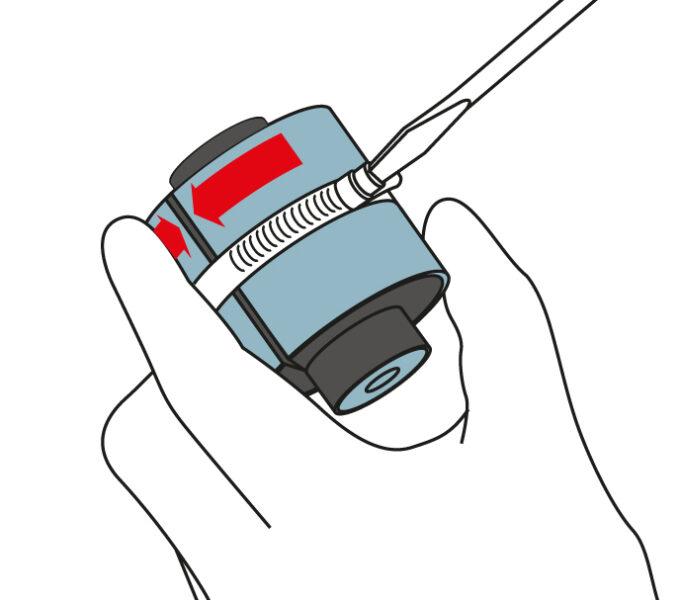

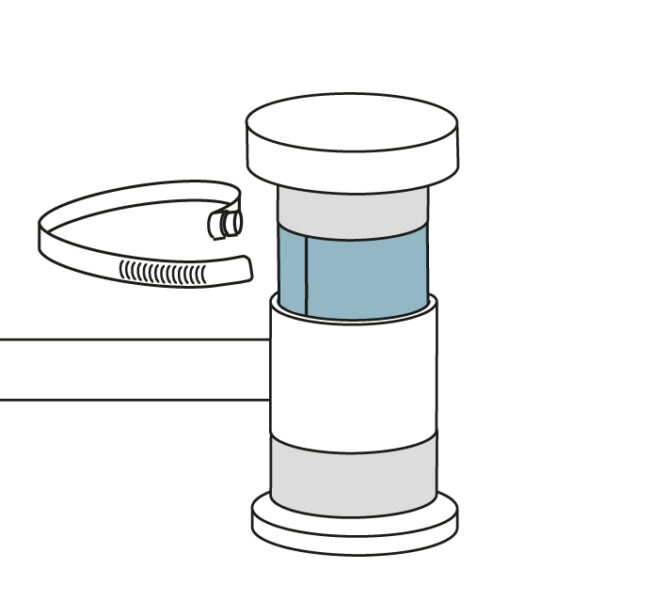

6

We remove the clamp to further press the bushing in.

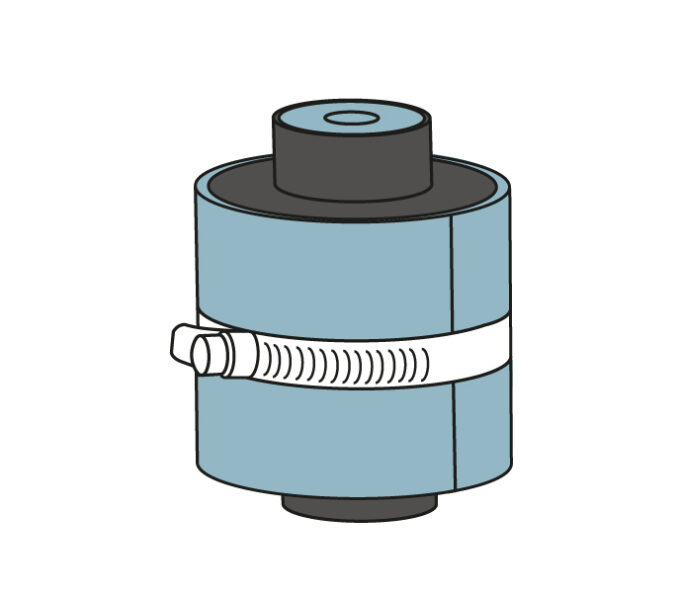

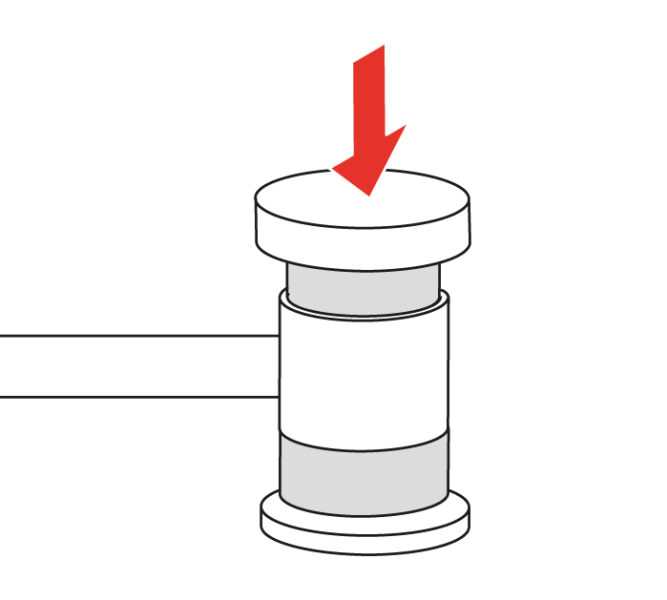

7

Final pressing the bushing in.

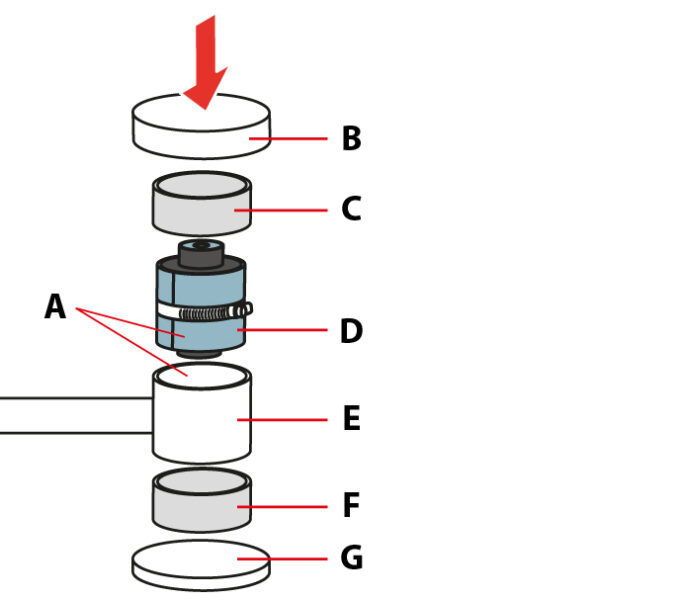

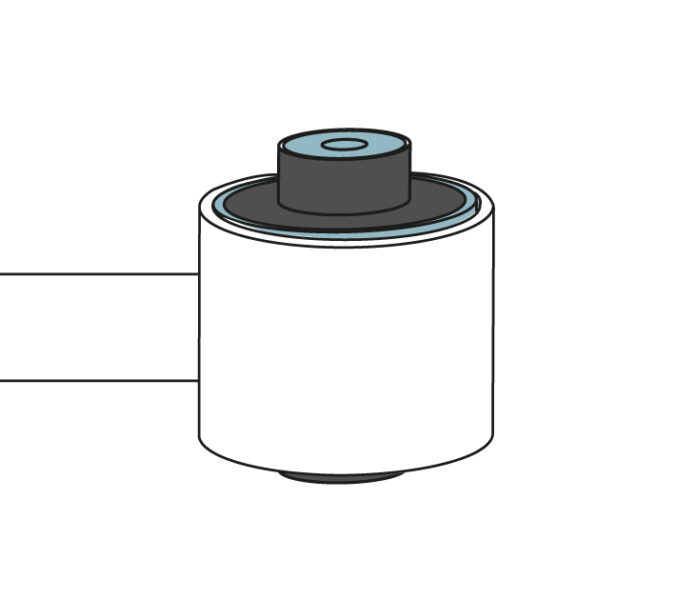

8

Correctly pressed in element.