Loss of tightness on the working piston is a common brake servo failure. The symptom of the fault is a characteristic hissing sound when pressing the brake. This fault can be easily repaired by replacing the gasket with a new one. The replacement process is not complicated, but care must be taken not to damage the piston surface. Even a minor scratch on the piston may result in the need to replace the entire element.

We present below the subsequent stages of replacing the gasket:

1

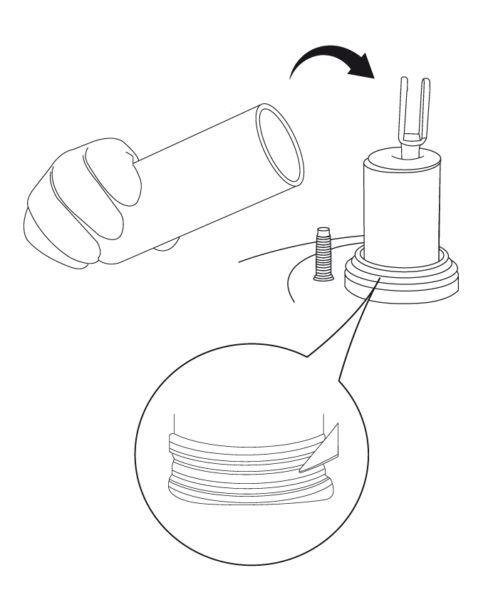

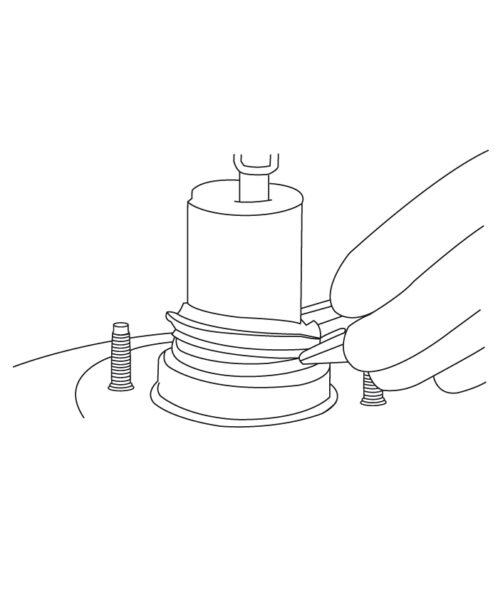

Remove the used seal, preferably with a plastic spatula, so as not to scratch the internal piston. Even the smallest scratch may lead to loss of tightness, which will result in the need to replace the entire element.

2

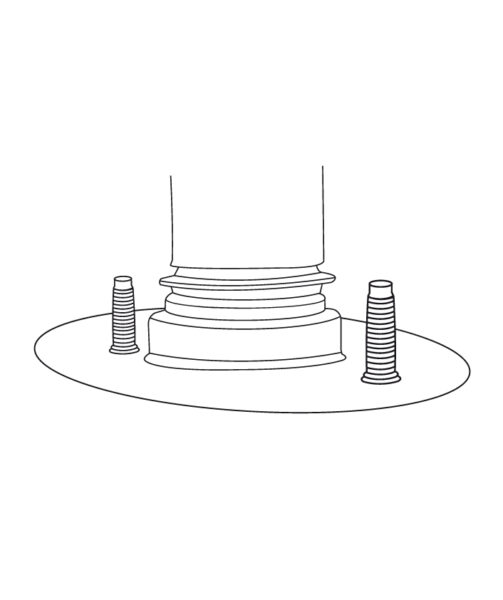

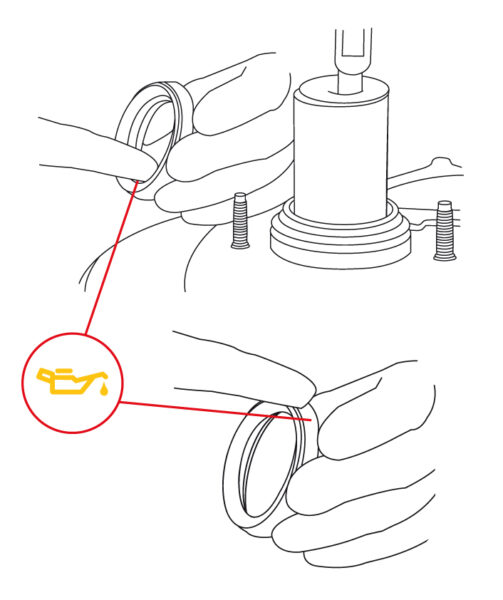

After removing the old seal, thoroughly clean the outside of the piston. Then thoroughly lubricate the new gasket with the included silicone grease on the inside and the lower part to the flange on the outside. Only silicone grease should be used, as other substances may weaken or damage the element over time.

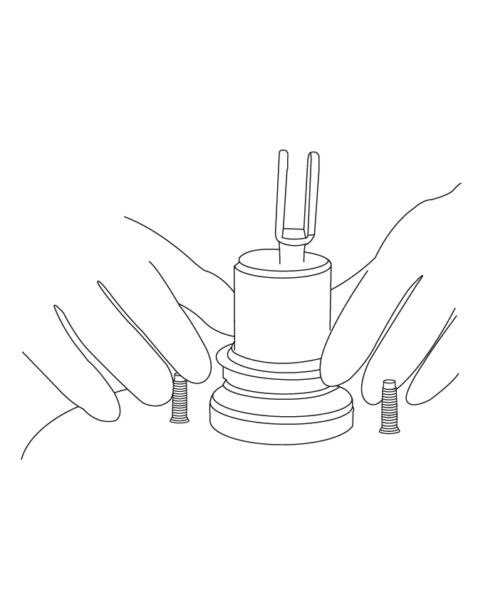

3

Push the lubricated sleeve onto the piston so that it is right next to the housing.