What is the driveshaft for?

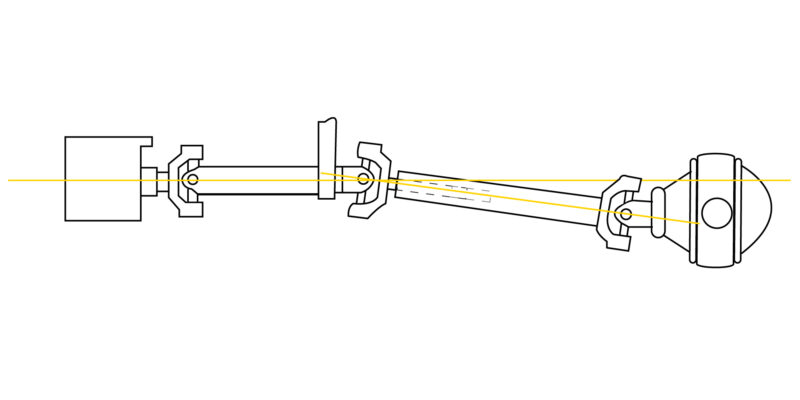

The driveshaft, also known as propeller-shaft, tail shaft or Cardan-shaft (the name taken from Cardan joints used in driveshafts) is a component of vehicle’s drive system and its purpose is to transfer torque from engine to the rear wheels. It seems to be quite simple task – you just need to connect one side to the engine and other to the transmission. The engine will pass rotation to the shaft and then to wheels. The problem is that rear suspension during the ride is moving in relation to the engine. That is why drive shaft cannot be constructed as one solid element and needs additional components to work correctly also while suspension movement.

Drive shaft is used in rear-wheel drive cars, as well as in 4WD and AWD cars.

The drive shafts are made of steel, aluminum alloys, and in sports cars also of carbon fiber to reduce weight (eg Nissan 350Z). The drive shaft is divided into 2 or more parts due to the reduction of vibrations caused by high rotational speed of the shaft.

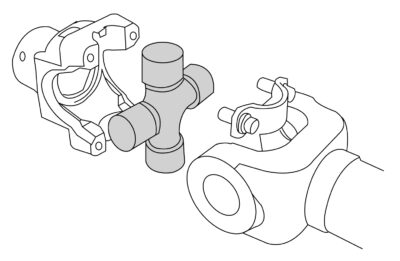

What are the U-joints (Universal joints)?

In order to ensure the possibility of rotation of two parts of the shaft relative to each other, universal joints are used, also known as cardan joints (from the name of Girolamo Cardano, who constructed this mechanism in the 16th century). These connections, as the name suggests, consist of a cross, the arms of which are ended with bearing elements. These elements can be maintenance-free (when the bearing element is tightly protected against the leakage of lubricant) and those that should be regularly serviced by refilling the lubricant. The already mentioned bearing elements are connected alternately with the fork elements of the shafts.

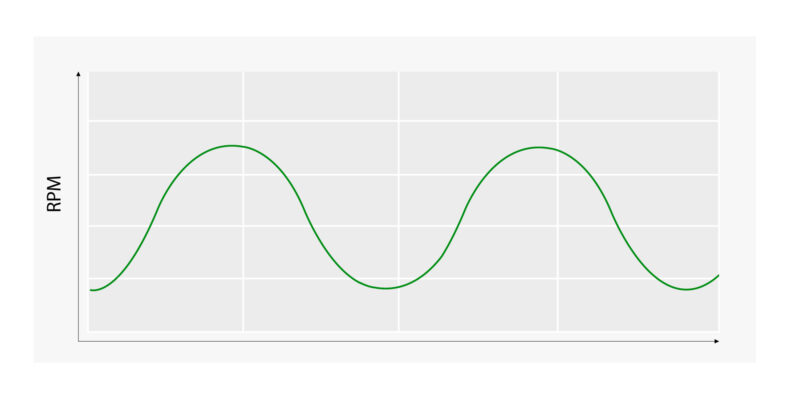

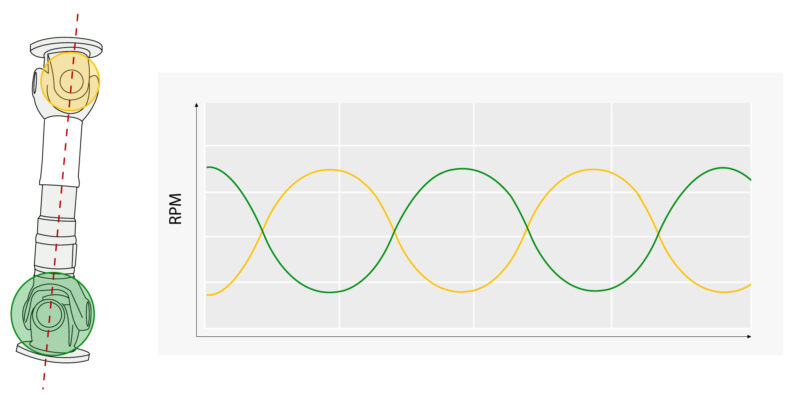

This solution, while helping to transfer torque between shafts that are not aligned, is not without drawbacks. First, depending on the number of revolutions, the swing angle is limited (the greater the number of revolutions, the smaller the angle). Second, the solution is not homokinetic. This means that at the moment of rotation of the input shaft (which sets the torque), the output shaft (which receives the torque) moves at a variable speed -it is called velocity fluctuation. The rotation speed of the output shaft changes 4 times during each revolution.

The solution to this problem is the use of a second universal joint. In this case, it is set offset so that when one joint slows down, the other accelerates, which eliminates the difference in the speed of rotation of the output shaft.

What is support bearing and what is it for?

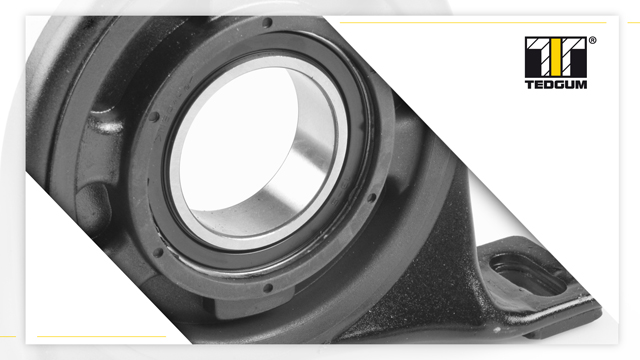

When there are 2 or more shaft parts in the system, it is necessary to use the shaft support (support bearing or center support bearing for the main support in rear drive shaft), which is an element consisting of a bearing, a rubber element and a metal housing. The purpose of the support is to hold the shaft in the correct position, and also to reduce vibration and noise generated by shaft rotation. Bearing located in the shaft support operates at very high revolutions. The rubber in the structure is loaded with vibrations, it is an element that is highly susceptible to damage.

Due to the characteristics of this material, the rubber element is also prone to ageing, so even with proper operation of the system, damage may appear on it after some time, which at some point will force the replacement of the entire element. In some supports, it is possible to replace the insert itself (bearing and rubber element), which, thanks to keeping the original housing, can significantly reduce the cost of replacement.

Damage to the support may not always be clearly visible. Sometimes, it can appear as a delicate incision that becomes visible only when a load occurs. Due to the rubber element, the center support bearing has its range of motion, however, if it is too large, it may indicate that the element is worn out.

Before center support bearing replacement, it is worth checking the condition of the entire driveshaft system, especially universal joints and rubber joints. If these components are damaged, replacing the support itself may only bring improvement for a short time, as when the other components malfunction, increased vibration can quickly damage it again.

If you notice noises and vibrations, especially during acceleration or heavy transmission loads (e.g. when climbing uphill), it is worth to check the condition of the support bearing. The bearing may be damaged, starting to resist the shaft more and more, which may result in increased vibration, friction noise, and overheating. Damage to the rubber element may lead to a change in the bearing position, which starts to run unevenly causing lower vibration damping.

Examples of center support bearings in our offer can be found at: Support bearings.

Flexible disc – what is it and why is it used?

The flexible shaft joint was developed and patented by Antonio Boschi. It is also called Giubo, which is a combination of the word “giunto” (meaning “connection” in Italian) and the name of the above-mentioned Italian engineer. It is an element usually consisting of a rubber disk, metal sleeves and an internal braid. The flex disc is placed between the shaft and the transmission. It provides vibration damping and a limited mobility. This element, as well as other components of the drive shaft system, is exposed to high overloads caused by the high rotational speed of the shaft and the torque transmitted by it. Even small cracks can cause additional vibrations. That can reduce the life of other components, such as shaft supports. Therefore, when disturbing symptoms occur, check all shaft components and replace them if damaged.

Examples of flexible discs in our offer can be found at: Flex rubber discs.